Now that all the parts are cut and everything fits like it should, It’s time to move on to getting this thing assembled!

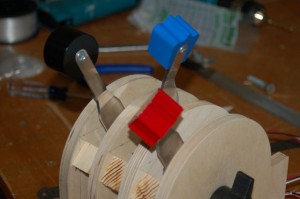

I made one more change to the original BRFS design:

Instead of using the recommended method for keeping the main support bolt from rotating when you tighten or loosen the friction knob, I installed a stove carriage bolt that has a squared area right underneath the bolt head. This prevents the bolt from turning once it’s drawn completely into the material.

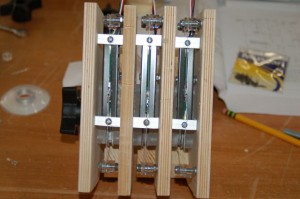

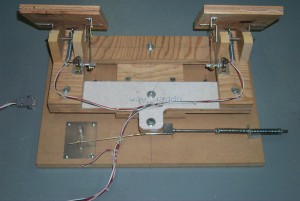

The first step is to get each lever rigged up:

The rigging line I used was 36 strand steel beading wire. This and the swag collars can be had at your local craft store.

I’m using a pull-pull system to actuate the slide pot – the geometry is similar to the BRFS throttle, but because my levers are symmetrical, I didn’t need to use the spring to keep tension on the line. I’ve also drilled two holes (only one is used) to attach the pull wires to the pot arm. Each hole that the rigging wire passes through has been carefully de-burred in order to make sure that no sharp edges existed that could cut the line over time.

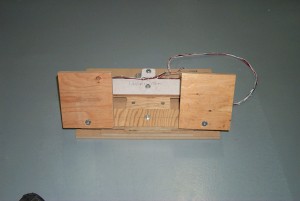

This is what it looks like from the bottom with all three lever assemblies installed.

The knobs are painted and they turned out really nice!

(don’t forget to click the “more” link below!)